Top Benefits of Using a Laser Cutting Machine for Your Projects?

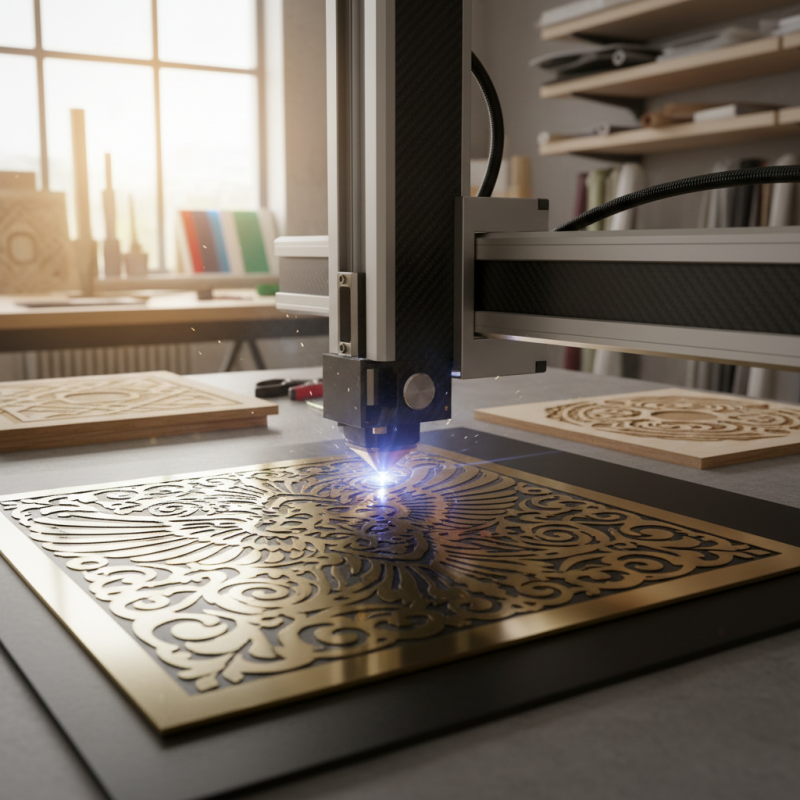

In today's manufacturing landscape, the use of a laser cutting machine has become a game changer. This advanced technology offers precise and efficient cutting, allowing for intricate designs that are hard to achieve with traditional methods. Imagine creating stunning artwork from metal or delicate patterns in wood. The possibilities are endless.

Not only does a laser cutting machine improve productivity, but it also reduces material waste. This aspect is crucial for environmentally conscious businesses. With each cut, you maximize the use of your raw materials. However, it requires careful planning and skill to avoid mistakes that could lead to costly errors.

While the benefits are clear, users must reflect on the initial investment. A laser cutting machine can be expensive. Is it truly worth it? For many, the answer lies in the efficiency and quality it delivers. Ultimately, embracing this technology means adapting to new challenges but also unlocking a world of creativity.

Overview of Laser Cutting Technology and Its Applications

Laser cutting technology has revolutionized many industries. It uses a focused beam of light to cut through materials with precision. This technology is applicable in fields like manufacturing, automotive, and even arts and crafts. The ability to create intricate designs with minimal waste is a huge advantage.

In practical terms, laser cutters can handle various materials. Metals, wood, and plastics can all be processed. However, different materials require different settings. This can be tricky. Users often need to experiment to achieve optimal results. Adjusting power, speed, and focus can significantly impact the final product.

Projects can sometimes go awry. Inexperience can lead to mistakes, such as improper settings or misaligned materials. These errors remind users of the importance of practice and learning. The evolving nature of laser cutting technology means there’s always something new to master. Embracing these challenges can lead to stunning outcomes.

Top Benefits of Using a Laser Cutting Machine for Your Projects

The bar chart above illustrates the top benefits of using a laser cutting machine in projects, rated on a scale from 1 to 10. Precision stands out as the most significant advantage, closely followed by speed, material versatility, reduced waste, and cost-effectiveness.

Enhanced Precision and Accuracy in Cutting Processes

Laser cutting machines offer remarkable precision and accuracy in various projects. This technology uses focused laser beams to slice through materials with extreme detail. Unlike traditional cutting methods, lasers create clean edges and intricate designs. This capability opens up endless possibilities for artists, designers, and manufacturers.

The benefits are evident in numerous applications, from creating delicate jewelry to intricate architectural models. The laser’s pinpoint accuracy reduces material waste, as it cuts exactly where intended. However, users must remain mindful of the learning curve. Mistakes in settings can lead to undesired outcomes. Adjusting the focus and speed is crucial for achieving the perfect cut.

In addition to precision, the versatility of laser cutting should not be overlooked. It accommodates a wide range of materials, including wood, metal, and plastic. Yet, experimenting with different thicknesses can be challenging. Each type of material reacts differently to heat, requiring careful adjustments. Embracing these variables can ultimately lead to innovative and eye-catching results.

Increased Efficiency and Speed in Project Execution

Laser cutting machines are revolutionizing the way projects are executed. They offer remarkable efficiency and speed, dramatically reducing the time needed for cutting materials. With a precision that traditional methods struggle to match, laser cutters can create intricate designs swiftly. This allows for complex projects to move forward without unnecessary delays.

In various industries, this speed translates directly into enhanced productivity. However, it is crucial to recognize that not all materials react well to laser cutting. Some may scorch or warp, leading to wasted resources and time. This reality forces users to experiment and adjust settings frequently, which can slow progress initially. Yet, with practice, the learning curve can lead to very effective outcomes.

Utilizing a laser cutting machine demands careful planning and thoughtful execution. Project managers must consider material compatibility and ideal settings. Even with the technology's advantages, missteps can happen. A minor error in settings can result in flawed designs. Thus, integrating laser cutting requires a balance of speed and meticulous attention to detail.

Versatility in Material Usage for Diverse Projects

Laser cutting machines offer remarkable versatility in material usage, which is a major benefit for various projects. Whether you are working with wood, acrylic, metal, or fabric, these machines provide precise cuts that suit different requirements. This adaptability allows creators to explore endless possibilities. For instance, a designer might choose plywood for a prototype but switch to acrylic for a more polished finish. The flexibility can enhance creativity.

One might face challenges when selecting materials. Not all materials behave the same under a laser, leading to unexpected results. For example, certain plastics can emit harmful fumes, while metals may require specific settings. This inconsistency calls for careful testing before finalizing any project. Users need to reflect on their material choices and understand how each reacts to laser cutting. Sometimes, a trial-and-error approach can yield better insights into material properties.

The efficiency of laser cutting also encourages experimentation. Artists can blend materials, creating unique effects not achievable with traditional methods. They may cut intricate designs into wood while incorporating metal accents. This fusion sparks innovation. Yet, even with such advanced technology, mistakes will happen. Miscalculations can occur, leading to material wastage. Learning from these missteps ultimately enhances skills and reinforces the creative process.

Cost-Effectiveness and Waste Reduction Benefits

Laser cutting machines are revolutionizing project development, particularly in cost-effectiveness and waste reduction. These machines offer precise cuts that minimize material wastage. For instance, a simple design can utilize more of the material, avoiding excessive scraps. This efficiency can significantly lower costs over time.

Moreover, the initial investment in laser cutting technology may seem substantial. However, the long-term savings often outweigh this upfront expense. Reduced labor costs and faster production times contribute to overall profitability. With increased accuracy, there's less chance of redoing projects, which further cuts down expenses.

Not everything is perfect, though. Some users may struggle with machine calibration. This can lead to misalignments, wasting the very materials they're trying to conserve. It's crucial to regularly maintain the machine to ensure optimal performance. Even small oversights can affect overall savings, encouraging users to reflect on their processes continually.

| Benefit | Description | Impact |

|---|---|---|

| Cost-Effectiveness | Laser cutting reduces material waste and labor costs by providing high precision cutting. | Lower operational costs and improved profit margins. |

| Waste Reduction | Utilizes advanced cutting techniques that significantly minimize scrap materials. | Environmental sustainability and reduced disposal costs. |

| Speed | Laser cutting machines operate faster than traditional cutting methods, increasing productivity. | Faster project turnaround times. |

| Versatility | Ability to cut and engrave on various materials, including metals, plastics, and wood. | Wider range of project possibilities. |

| Precision | Offers high accuracy with minimal tolerance in cutting. | Enhanced product quality and reduced material wastage. |