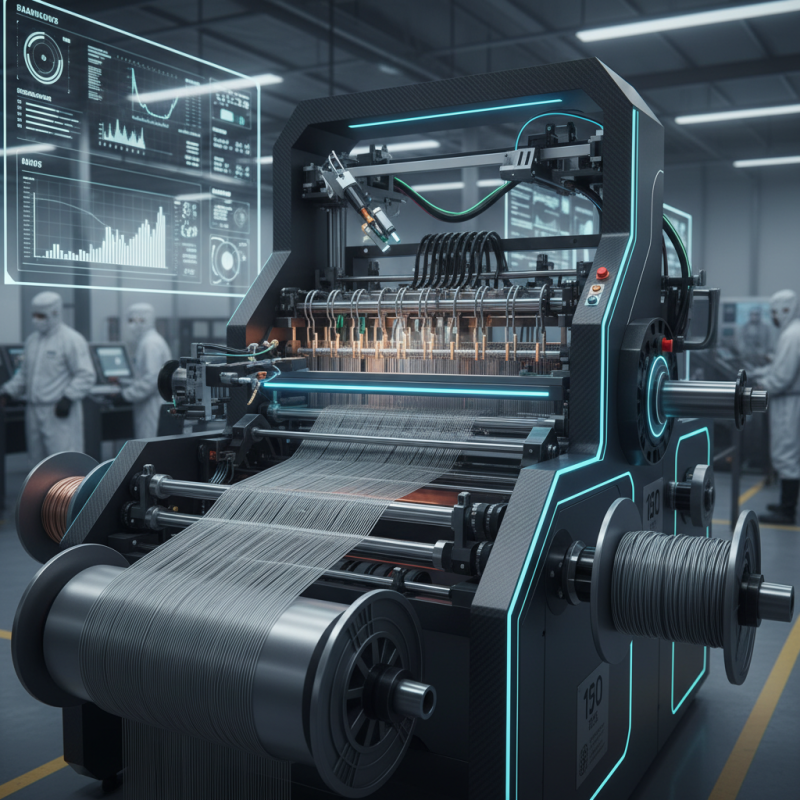

2026 Best Wire Mesh Weaving Machine for Your Manufacturing Needs?

The manufacturing industry constantly evolves, and selecting the right tools is crucial. A wire mesh weaving machine is essential for producing high-quality wire mesh products. The ideal machine can boost production efficiency and reduce operational costs.

In 2026, various options are available, each with unique features. Some machines excel in speed, while others focus on precision. It's essential to assess your manufacturing needs to choose wisely. Consider factors like material types, mesh sizes, and production volumes.

While the latest technology often boasts impressive capabilities, not every machine may suit your requirements. Reflection on past choices is important. What worked before may not be ideal now. Evaluating performance metrics from different models is essential. Your choice will impact overall productivity and profitability. Choose thoughtfully.

Overview of Wire Mesh Weaving Machines in Manufacturing

wire mesh weaving machines play a crucial role in various manufacturing sectors. These machines are designed to create high-quality wire mesh products, which are essential in industries like construction, automotive, and filtration. According to a recent industry report, the global market for wire mesh is expected to reach USD 12 billion by 2026, indicating robust growth.

When selecting a weaving machine, manufacturers must consider several factors, including speed, accuracy, and the range of mesh sizes. The right machine can dramatically improve production efficiency and reduce material waste. Reports suggest that up to 30% of production costs can come from inefficiencies. Thus, investing in the best equipment is vital.

**Tip:** Always analyze your specific needs before making a purchase. Think about your production volume and desired product quality.

Selecting the wrong machine can lead to product defects and delays. A flawed weaving process may result in weak mesh that doesn't meet specifications. Regular maintenance is key to ensuring the longevity and performance of the machines.

**Tip:** Schedule routine checks and keep a maintenance log to avoid unexpected downtime. Investing in training for operators can also help achieve optimal performance.

Key Features to Look for in a Wire Mesh Weaving Machine

When selecting a wire mesh weaving machine, key features are essential. Pay attention to the machine's weaving speed. Faster machines can boost productivity, but they may compromise quality. A balance is necessary. Precision is vital. Look for machines that can maintain tight tolerances. Variations in mesh size can impact the final product.

Consider the ease of operation as well. User-friendly controls reduce training time. A complicated interface can lead to errors. Durability is another critical aspect. Machines are an investment, and a robust design extends their lifespan. Regular maintenance is essential. Machines that are hard to service can incur additional costs over time.

Also, check the versatility of the machine. It should accommodate various mesh patterns and sizes. This flexibility allows adaptation to different projects. The integration of technology is crucial too. Modern machines often feature automation for efficiency. However, tech can also complicate repairs if something goes wrong. Being aware of these factors helps make an informed decision. Weigh the pros and cons carefully.

Top Brands and Models for Wire Mesh Weaving in 2026

In 2026, wire mesh weaving machines play an essential role in manufacturing. Industries are constantly evolving. Data shows a projected growth rate of 5% in the wire mesh sector. Companies need reliable machines to keep up. This demand drives advancements in technology and design.

Top models are seeing innovations in speed and efficiency. Some machines can weave at an impressive 40 meters per minute. Others focus on versatile applications, catering to various industries. Flexibility is key. Reports indicate a significant increase in demand for custom mesh sizes. The need for robust machinery that can adapt to these specifications is critical. However, not all machines perform equally. Some may struggle with certain materials.

Manufacturers must reflect on their choices. Investing in high-quality equipment can offset costs in the long run. Faulty machines can lead to production delays. A well-informed decision is vital. Industry surveys suggest that about 30% of users experience operational challenges. Understanding these pitfalls is step one towards better production. Many companies still overlook this aspect, risking efficiency and profitability. The landscape is changing. Adapting to these needs will define success in wire mesh weaving.

2026 Best Wire Mesh Weaving Machines Performance Comparison

Comparative Analysis of Performance and Efficiency

When selecting a wire mesh weaving machine, performance and efficiency are critical. Recent industry data reveals that machines with high-speed capabilities can produce up to 50% more mesh per hour compared to standard models. This is crucial for meeting increasing production demands in various sectors. However, speed isn't the only factor to consider; the durability of the machinery plays a significant role in overall efficiency.

Efficiency also depends on the technology employed in the weaving process. Automated machines reduce manual intervention, leading to fewer errors. A study found that automation can decrease operational costs by approximately 30%. In contrast, some traditional machines, while cheaper, often result in increased downtime and higher maintenance costs. This highlights a frequent concern: balancing initial investment with long-term gains.

Moreover, not all machines are created equal when it comes to flexibility. Some can only produce specific types of mesh. Businesses may find themselves constrained by their equipment, which can hinder innovation. Thus, evaluating a machine's adaptability to different weaving patterns is essential. Investing in versatile solutions is often a better long-term strategy, though it may require more upfront resources.

Cost Considerations and Budgeting for Your Purchase

When investing in a wire mesh weaving machine, budgeting is crucial. Costs vary widely depending on features and capabilities. A basic machine may set you back a few thousand dollars, while advanced models can reach tens of thousands.

Consider not just the purchase price but also the ongoing costs. Maintenance, spare parts, and even energy consumption should be factored into your budget.

Additionally, research the market to find the best value. Often, more cost-effective options exist that provide similar quality. You may encounter machines with unnecessary features that inflate the price. Remember, getting the right machine is about balancing your needs with your budget.

Evaluate your production goals and needs carefully. This reflection can help avoid overspending. Sometimes, cheaper machines may offer a more straightforward operation. Do not overlook second-hand machines either; they can be a great budget-friendly solution.

Adjusting expectations and being open-minded can lead to smarter financial decisions.