How to Choose the Best Geomembrane Welding Machine?

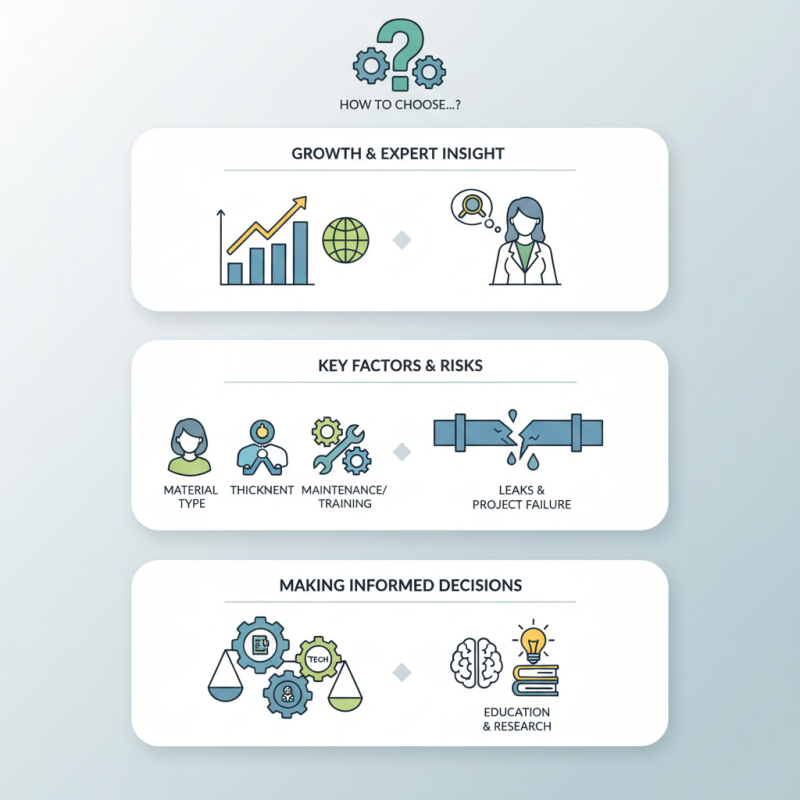

In the modern construction industry, choosing the right geomembrane welding machine is crucial for successful project execution. According to a report by the Geosynthetic Institute, the geomembrane market is expected to grow by 10% annually. This growth highlights the need for efficient welding solutions. Experts emphasize that selecting the right machine can significantly impact project outcomes. Dr. Alice Green, a leading geomembrane technology expert, states, "The right welding machine is essential for ensuring the integrity and longevity of geomembrane installations."

When assessing options, various factors come into play. The type of material, thickness, and environmental conditions all affect machine performance. Additionally, users often overlook the importance of operator training and maintenance schedules. The welding process requires precision. A poorly executed weld can lead to leaks, which compromise project integrity.

While some machines offer advanced features, they may not suit every application. The challenge lies in balancing technology with practicality. Investing in a high-quality geomembrane welding machine is vital, but understanding project-specific needs is equally important. Mistakes in machine selection can result in costly delays. As the industry evolves, ongoing education and research will prove indispensable for professionals aiming to make informed decisions.

Factors to Consider When Selecting a Geomembrane Welding Machine

When choosing a geomembrane welding machine, several factors come into play. The welding technology you select is crucial. Hot wedge, extruder, and radio frequency welding are common options. Each method has its own advantages and challenges. Assess your specific project needs before making a decision.

Take note of the machine's power requirements. Some projects may require a more powerful machine for thicker materials. Additionally, consider its portability. A lighter, more compact machine could be beneficial for fieldwork. However, heavier machines often provide stability and durability.

Tips: Always verify the machine's compatibility with various geomembranes. Testing the welds in different conditions can reveal potential weaknesses.

Maintenance is another factor. Look for machines that are simple to clean and maintain. If maintenance is challenging, it might lead to operational delays. Reflect on your team's expertise. Choosing a complex machine might require more training. This could impact your project's timeline. Invest time in training for better outcomes.

How to Choose the Best Geomembrane Welding Machine? - Factors to Consider When Selecting a Geomembrane Welding Machine

| Feature | Importance | Recommended Value |

|---|---|---|

| Welding Technology | High | Hot Air or Extrusion |

| Power Output | Medium | 220-240V |

| Temperature Control | High | Digital Display |

| Speed Settings | Medium | Variable Speed |

| Weight | Low | Less than 30 kg |

| User-Friendliness | High | Easy Operation |

| Warranty Period | Medium | At least 1 year |

Understanding Different Types of Geomembrane Welding Technologies

When selecting the best geomembrane welding machine, understanding the various welding technologies is crucial. There are several key types to consider. Hot wedge welding is widely used for thermoplastic materials. This method employs a heated wedge to melt the membranes together. Researchers indicate that it provides strong, durable seams. However, it requires skilled operators to avoid common mistakes like uneven heating.

Another significant technology is extrusion welding. This involves a welding rod being melted and extruded into the seam. According to industry reports, this method is known for its versatility. It works well for complex geometries. Yet, achieving the right tension and speed is challenging. An improper setup can lead to weak joints and costly repairs.

Additionally, there is the use of radio frequency (RF) welding, which is suitable for specific applications. It is known for its speed, but not all materials are compatible. Some professionals report that inconsistent results can arise if the setup isn’t precise. The choice may ultimately depend on project specifics. Understanding these technologies can lead to more informed decisions, avoiding regret later on.

Key Specifications to Evaluate: Power, Speed, and Temperature Control

Choosing the right geomembrane welding machine is crucial for efficiency. Power is the first specification to consider. Machines with higher power ratings can manage thicker geomembranes. According to a recent industry report, machines with a power range of 3,500 to 5,500 watts are popular. They provide optimal performance for demanding tasks. However, excessive power can lead to overheating. Operators must monitor equipment to prevent damage.

Speed is another key factor. Different applications require varying welding speeds. The average welding speed for geomembranes is between 5 to 12 meters per minute. This range allows flexibility for various projects. Yet, rapid welding can compromise seam quality. Testing and adjustments are often needed to balance speed and weld integrity.

Temperature control plays a vital role in achieving successful welds. Precision is necessary to avoid material damage. Many machines offer adjustable temperature settings, usually between 200°C and 600°C. This flexibility is essential for different geomembrane materials. Nonetheless, incorrect temperature settings can lead to failures. Operators should regularly calibrate their machines to ensure reliability.

Industry Standards and Certifications for Geomembrane Welders

Choosing the right geomembrane welding machine involves understanding industry standards and certifications. These standards ensure the products meet safety and performance requirements. Compliance with established norms is crucial for all projects. Welding machines should have certifications to prove reliability.

Tips: Always check certifications before purchasing. Look for machines that comply with regional standards. Safety should be a priority.

Weld quality is paramount. Poor quality welds can lead to leaks, which are costlier to repair. Make sure the machine features control systems for consistent heating. Operators must also be trained to recognize potential errors in the welding process.

Tips: Consider training programs for your team. Educated operators can spot mistakes early. Regularly audit your welding processes to ensure compliance.

Geomembrane Welding Machine Performance Comparison

Maintenance and Support: Ensuring Longevity of Your Welding Equipment

Maintaining a geomembrane welding machine is crucial for its longevity. Regular inspections help identify wear and tear. Check for any signs of damage, such as frayed cables or loose connections. Keeping the machine clean can prevent overheating. A clean workspace allows for smooth operation too.

Support is just as important as maintenance. Training sessions can empower operators to use the equipment effectively. Knowing when to call for expert help is vital. Sometimes, minor issues can escalate, leading to costly repairs. Create a logbook for all maintenance activities. This will help track performance over time and highlight any recurring problems.

Inadequate care can lead to unexpected downtime. Many operators overlook the importance of small routine checks. Remember, consistency is key. Regular maintenance not only ensures efficient operation but also reduces long-term costs. Assessing machinery often can pay off significantly.