How to Choose the Right Tempered Glass Based on Industry Standards and Safety Ratings

When it comes to selecting the appropriate tempered glass for various applications, a clear understanding of industry standards and safety ratings is crucial. Tempered glass, renowned for its strength and thermal resistance, is widely used in both residential and commercial settings, including windows, doors, and facades. However, not all tempered glass products are created equal; different standards and ratings can significantly affect performance and safety. This guide aims to illuminate the key factors in determining the right type of tempered glass, whether for architectural design, safety features, or aesthetic preferences. By delving into the specifications and certifications associated with tempered glass, consumers can make informed choices that ensure durability and compliance with relevant safety regulations, ultimately enhancing both functionality and peace of mind in their applications.

Understanding the Importance of Industry Standards for Tempered Glass

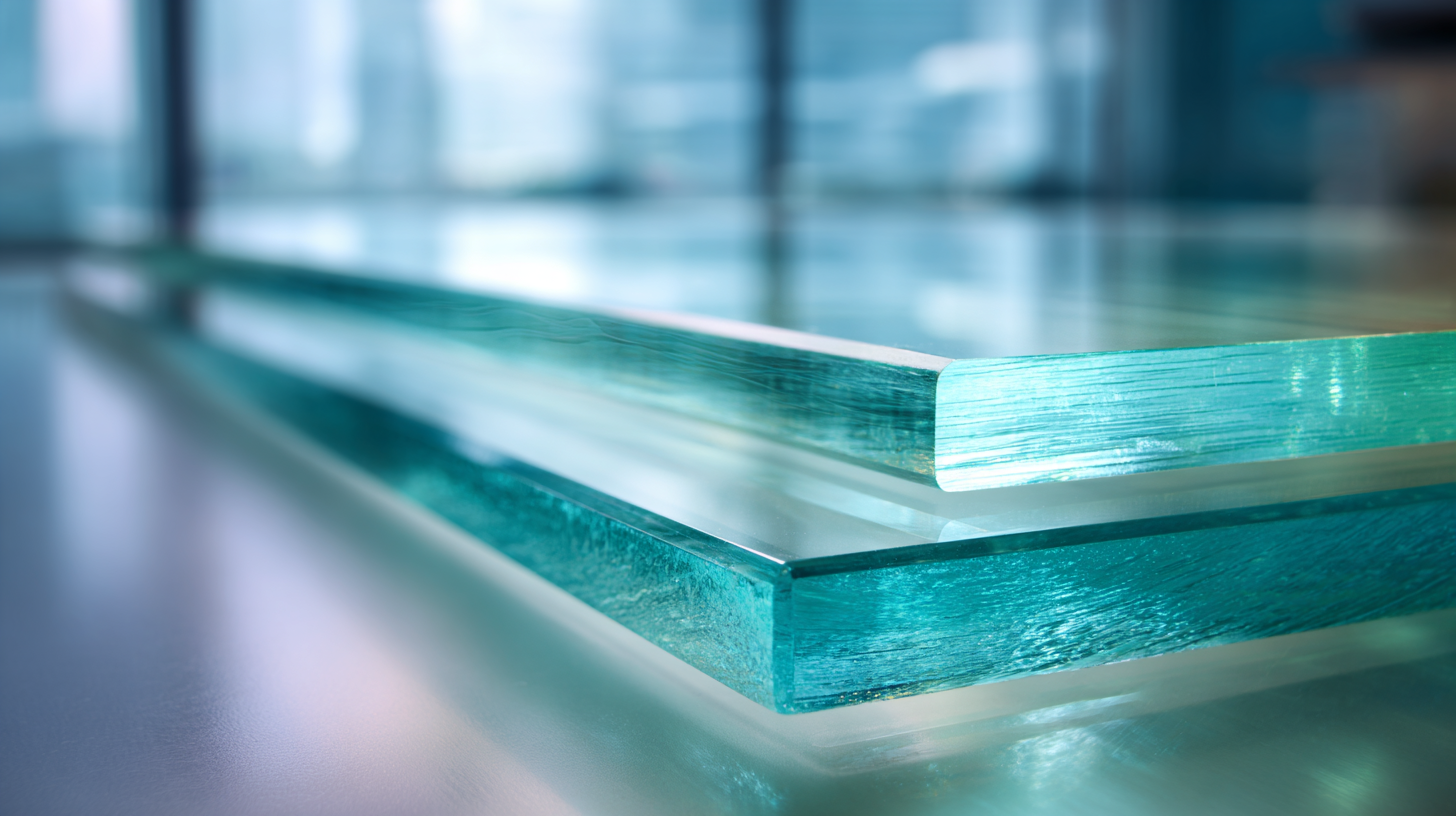

When selecting the right tempered glass for various applications, understanding industry standards is crucial. These standards ensure that the glass meets safety and performance criteria, making it suitable for use in construction, automotive, and various other sectors. Compliance with these standards not only guarantees the structural integrity of the glass but also helps prevent potential accidents caused by material failure. Each industry has specific requirements that dictate the thickness, strength, and thermal resistance of tempered glass, which underscores the importance of thorough knowledge regarding these benchmarks.

Additionally, the growing demand for glass testing equipment reflects the increasing emphasis on safety and quality assurance in the tempered glass market. As the market size for glass testing equipment is projected to grow from $245 million in 2022 to $388 million by 2030, with a compound annual growth rate of 6.1% from 2024 to 2030, it highlights the industry's commitment to meeting stringent safety regulations. This trend not only enhances consumer confidence but also encourages manufacturers to adopt more rigorous testing protocols to adhere to evolving standards.

Key Safety Ratings to Consider When Choosing Tempered Glass

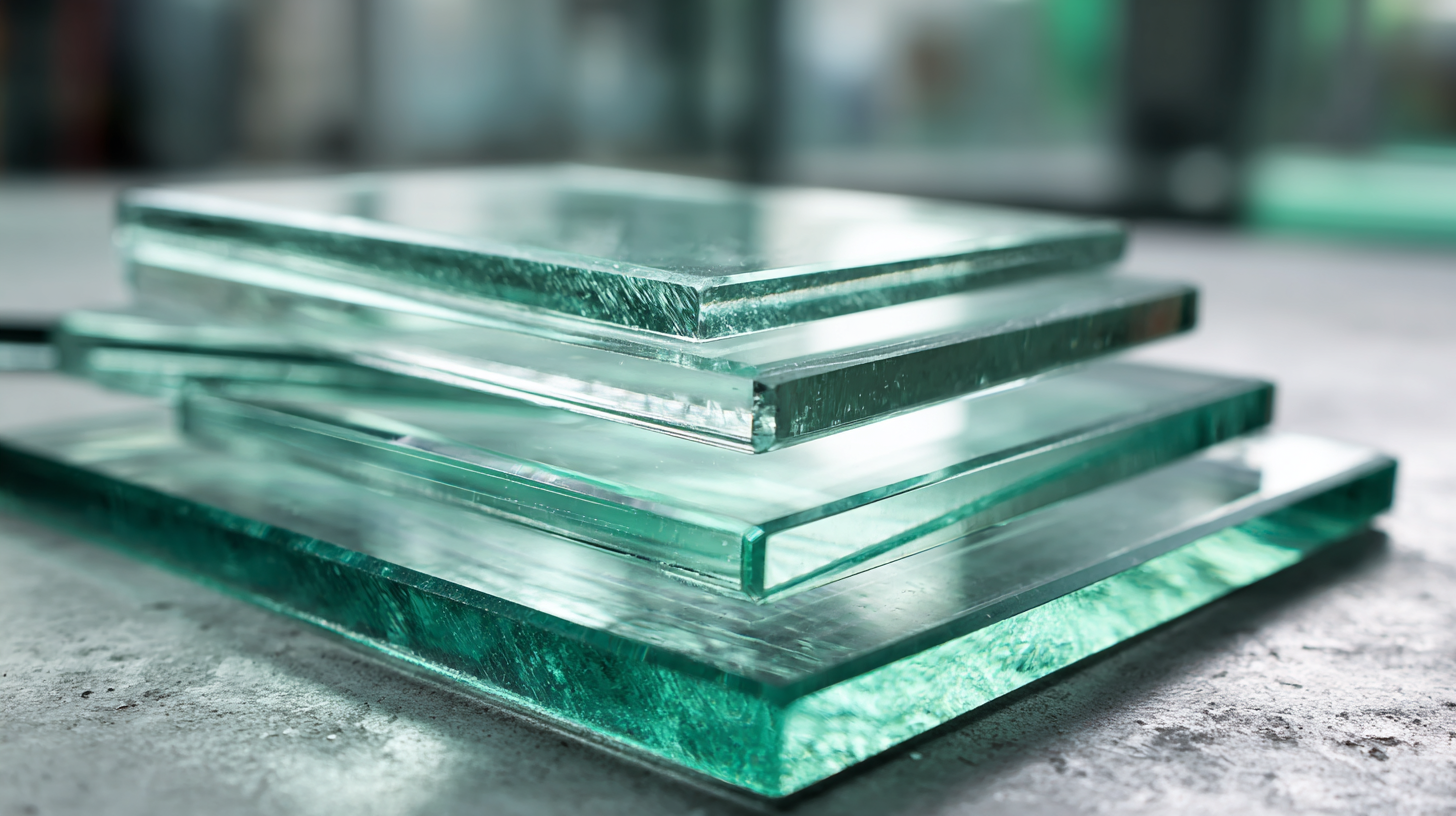

When selecting tempered glass, it's crucial to consider key safety ratings that reflect the glass's performance under stress and impact. One of the most widely recognized standards is the ASTM C1048, which outlines the requirements for heat-treated glass. According to industry data, tempered glass subjected to this standard can withstand temperature differentials of up to 250°F, making it an ideal choice for environments with fluctuating temperatures. Additionally, safety ratings like the ANSI Z97.1 specify that tempered glass must not break into sharp or dangerous shards, ensuring a higher level of safety for end-users.

Tips for choosing the right tempered glass include evaluating the specific application—whether it’s for windows, doors, or partitions. Ensure that the glass meets the required ASTM and ANSI standards for your project. It's also beneficial to check for certifications from reliable organizations such as Underwriters Laboratories (UL) or the Glass Association of North America (GANA), which can provide additional assurance regarding the glass's durability and safety features.

Another aspect to consider is the thickness of the tempered glass; a thicker pane generally offers better impact resistance. According to a report from the Glass Association, ¼ inch (6mm) thick tempered glass is recommended for residential applications, while commercial settings may require glass thicknesses of ½ inch (12mm) or more to meet increased safety demands. Always consult an industry professional for tailored advice specific to your needs.

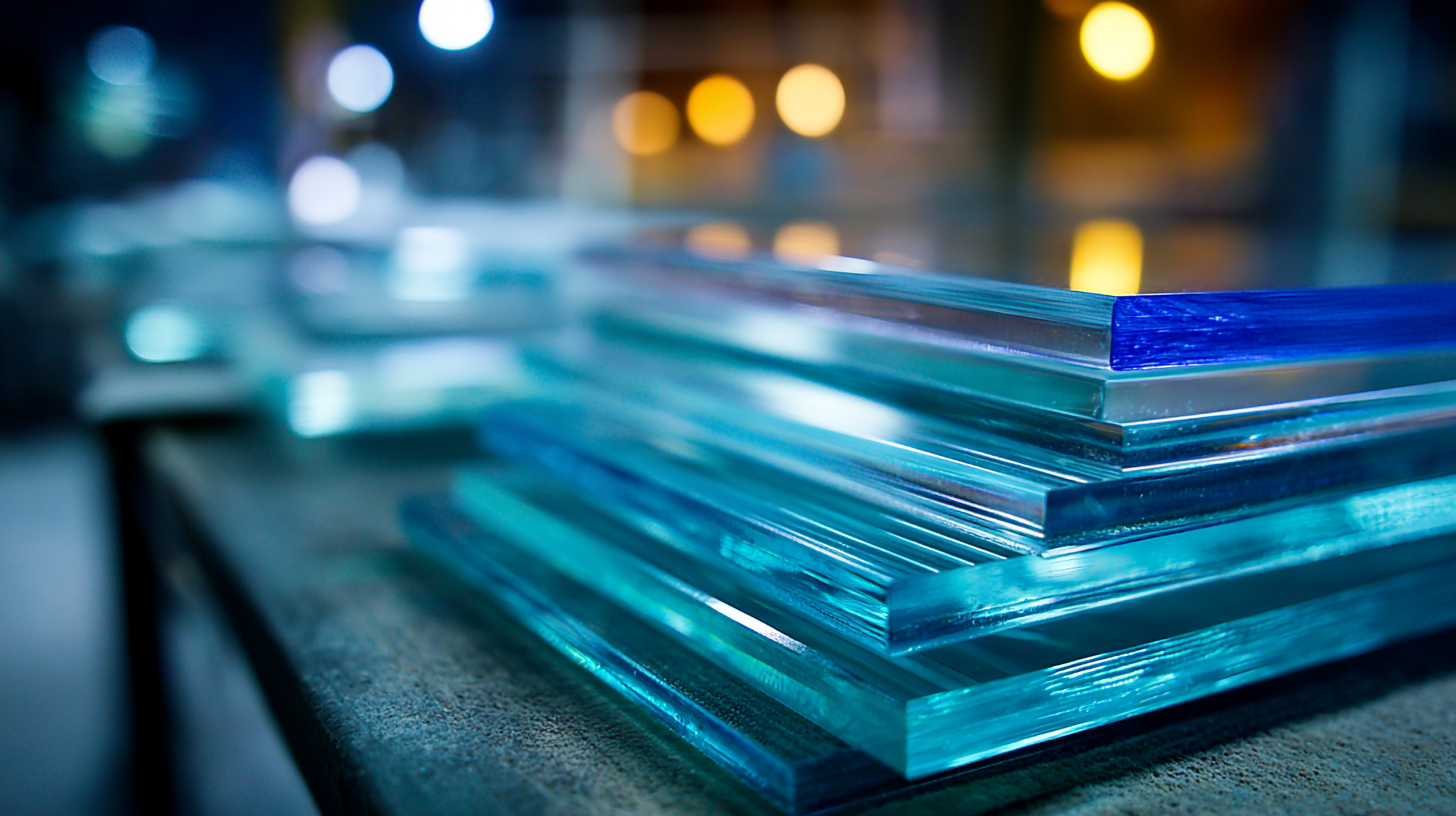

Evaluating the Different Types of Tempered Glass for Specific Applications

When selecting tempered glass for specific applications, it is essential to consider various types and their respective industry standards and safety ratings. Tempered glass serves diverse purposes, from structural components to mobile device protection. For instance, recent advancements highlight the use of insulating aerogel-filled glass bricks which enhance structural stability while being energy-efficient. This novel solution is ideal for translucent walls in architectural designs, showcasing the versatility of tempered glass in modern construction.

**Tips:** Always evaluate the thermal tempering process involved in your chosen glass, as this significantly influences its strength and resistance to thermal stress. Additionally, keep in mind the optical properties; understanding potential distortions can help in selecting glass that meets both aesthetic and functional requirements for your project.

Moreover, the application of specialized antibacterial coatings for mobile phone glass protectors represents another exciting trend. Such enhancements can make tempered glass not only durable but also hygienic, catering to contemporary consumer needs. Choosing the right type of tempered glass based on these innovative applications ensures optimal performance and safety in your specific use case.

Factors Influencing the Selection of Tempered Glass Based on Usage

When selecting tempered glass, several key factors aligned with usage must be considered to ensure safety and compliance with industry standards. One predominant factor is the glass thickness, which varies depending on its application. According to the Glass Association of North America (GANA), thicker tempered glass (typically exceeding 6mm) is recommended for applications such as commercial facades and high-traffic areas due to its increased impact resistance. This is vital in reducing the risk of shattering and providing improved structural integrity.

Another crucial aspect influencing the selection is the heat treatment process and its resulting safety ratings. The American National Standards Institute (ANSI) specifies that tempered glass should meet the ASTM C1048 standards, which include rigorous testing for thermal stress and mechanical strength. For instance, tempered glass used in exterior applications must withstand drastic temperature variations, often reaching upwards of 800°F during manufacturing. Employing certified tempered glass not only adheres to safety protocols but also enhances energy efficiency and performance, making it essential for architects and builders to choose products that align with these standards based on their specific project requirements.

How to Choose the Right Tempered Glass Based on Industry Standards and Safety Ratings

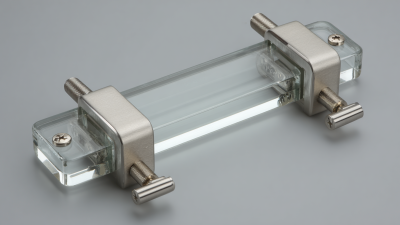

Comparing Supplier Certifications and Compliance with Safety Standards

When selecting tempered glass for various applications, it’s crucial to consider the supplier certifications and their compliance with industry safety standards. For instance, tempered glass used in construction must meet the guidelines established by the American National Standards Institute (ANSI) and the American Society for Testing and Materials (ASTM). According to a report by the Glass Association of North America, compliance with these standards ensures that the glass can withstand significant thermal and mechanical stresses, which is vital in high-rise buildings and other structures that require enhanced safety measures.

Moreover, different industries have specific safety ratings that must be adhered to. For example, automotive tempered glass is required to meet the standards set by the Federal Motor Vehicle Safety Standards (FMVSS). A study from the National Highway Traffic Safety Administration indicates that properly certified automotive glass can reduce the risk of injury during collisions by up to 25%. Ensuring that suppliers hold relevant certifications not only affirms their commitment to quality but also significantly contributes to the overall safety and reliability of the end product. Thus, comparing supplier credentials against established safety ratings is essential for making informed choices in tempered glass procurement.

Related Posts

-

How to Choose All Glass Solutions for Maximum Energy Efficiency in Modern Construction

-

7 Best Benefits of Installing Tempered Glass Doors in Your Home

-

What is the Innovation Behind Sliding Door Systems

-

5 Essential Tips for Choosing Aluminum Doors to Boost Energy Efficiency

-

How to Select the Right Glass Door Hardware for Your Home Design

-

How to Choose the Best Aluminum Doors for Your Home Upgrade