Why Are Cooling Towers Essential for Industrial Processes?

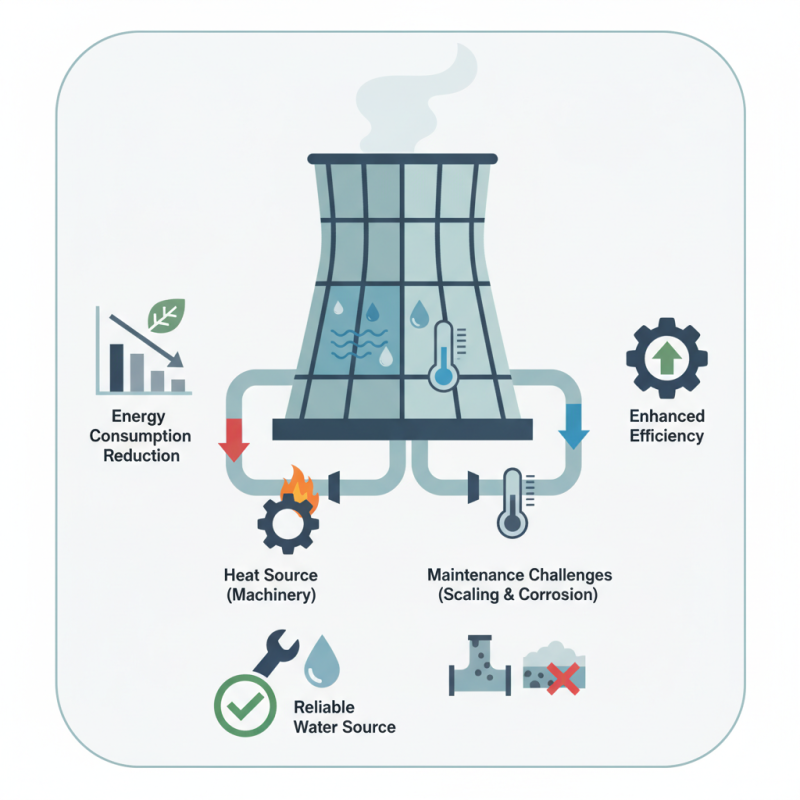

cooling towers play a vital role in various industrial processes. They manage heat, reduce energy consumption, and enhance efficiency. In many industries, maintaining optimal temperatures is crucial. A malfunctioning cooling tower can lead to significant losses in productivity.

These structures work by dissipating excess heat from machinery and systems. Through evaporation, cooling towers lower water temperatures. This process helps in cooling industrial equipment effectively. The demand for water in cooling processes is high. Ensuring a reliable water source is necessary.

However, while cooling towers are essential, they also present challenges. Regular maintenance is crucial to prevent issues like scaling and corrosion. Neglecting upkeep can result in reduced efficiency and higher operational costs. Understanding the importance of cooling towers can guide industries toward better practices.

Understanding the Functionality of Cooling Towers in Industry

Cooling towers play a critical role in industrial processes by regulating temperatures. They dissipate excess heat generated in manufacturing or power generation. This keeps equipment operating efficiently, preventing overheating or failure.

These towers work by circulating water. Hot water from processes flows into the cooling tower. Air is drawn in, and this interaction cools the water. The cooled water then returns to the system. This cycle maintains optimal temperatures.

However, not all cooling towers operate at peak efficiency. Design flaws or poor maintenance can hinder performance. Industries need to routinely assess their systems. Effective cooling towers are vital for sustainability and operational efficiency.

The Importance of Heat Exchange in Industrial Processes

Heat exchange is vital in industrial processes. It allows for effective temperature regulation, ensuring operations run smoothly. According to a report by the International Energy Agency, heat exchange systems can improve energy efficiency by up to 30%. Efficient cooling towers play a crucial role here. They remove excess heat generated from various processes, maintaining optimal temperature conditions.

In many industries, the failure to manage heat can lead to equipment damage. This risk emphasizes the importance of reliable heat exchange systems. For instance, in petrochemical plants, overheating can damage pipelines or reactors. A study by the American Society of Mechanical Engineers highlighted that 30% of industrial downtime is due to heat-related failures. This statistic indicates the need for robust cooling systems.

While cooling towers are essential, not all systems are efficient. Some facilities struggle with outdated technology, leading to increased operational costs. Inadequate maintenance can lead to inefficient heat exchange. This inefficiency not only raises expenses but also contributes to environmental issues. Regular assessments and upgrades can help in maximizing the effectiveness of heat exchange systems, ensuring industries remain competitive and sustainable.

Types of Cooling Towers Used in Various Industries

Cooling towers play a critical role in industrial processes. They help regulate temperature, ensuring systems operate efficiently. Different industries rely on various types of cooling towers to meet their unique needs.

Open-circuit cooling towers are commonly used in power plants and manufacturing. These towers expose water to air, promoting evaporation. This method effectively dissipates heat. Yet, they can be less efficient in humid climates. Closed-circuit cooling towers, on the other hand, use a heat exchanger to cool fluid. This design minimizes water loss but requires more maintenance.

Some industries opt for hybrid cooling towers. These combine open and closed systems. They offer flexibility and adapt to varying heat loads. However, they can be more complex to operate. Each type of cooling tower presents its challenges. Understanding these options is vital for optimal operation.

Why Are Cooling Towers Essential for Industrial Processes? - Types of Cooling Towers Used in Various Industries

| Cooling Tower Type | Application Industry | Cooling Capacity (kW) | Efficiency (%) | Water Consumption (m³/h) |

|---|---|---|---|---|

| Crossflow Cooling Tower | Power Generation | 1500 | 85 | 30 |

| Counterflow Cooling Tower | Chemicals | 2000 | 90 | 25 |

| Natural Draft Cooling Tower | Steel Manufacturing | 3000 | 80 | 40 |

| Hyperbolic Cooling Tower | Oil Refinery | 5000 | 88 | 35 |

| Plate Type Cooling Tower | Food Processing | 1000 | 95 | 20 |

Factors Influencing Cooling Tower Efficiency

Cooling towers play a crucial role in industrial processes. Their efficiency is influenced by several factors. One key element is the design of the tower itself. A well-designed cooling tower maximizes airflow and surface area. This enhances heat exchange, leading to better cooling performance.

Water quality also significantly impacts efficiency. Minerals and impurities can accumulate, forming scale and reducing heat transfer efficiency. Regular maintenance is essential to prevent these issues. Chemical treatment of the water can help, but improper dosing may create other challenges.

Weather conditions are another critical factor affecting cooling tower performance. High temperatures and humidity levels can reduce cooling efficiency. Operators need to monitor these variables closely and adjust operations accordingly. The challenge lies in balancing these factors to maintain optimal efficiency.

Cooling Tower Efficiency Factors

Regulatory Standards and Environmental Considerations for Cooling Towers

Cooling towers play a critical role in maintaining industrial efficiency. As industries face increasing regulatory standards, compliance becomes vital. The U.S. Environmental Protection Agency (EPA) emphasizes that cooling towers can account for up to 30% of water usage in a facility. This raises concerns about water conservation and sustainability. Regulations often limit water temperature discharge to protect aquatic life. It is crucial for industries to monitor and manage their cooling systems accordingly.

Industries must adapt not only to regulations but also to environmental considerations. Climate change impacts water availability. A recent report indicated that cities may experience a 20% reduction in water supply by 2050. This makes efficient cooling tower operations even more important. Reducing water consumption can lead to significant savings and enhanced operational resilience.

Tips: Regular maintenance checks can extend the lifespan of cooling towers. Ensure that water systems are optimized to limit evaporation. Monitor local regulations frequently to stay compliant. Understanding these factors can guide industrial processes towards a more sustainable future.